The Science Behind Laser Cleaning

Laser Source: Laser pulse cleaning is initiated by employing a high-energy laser source, which emits short-duration pulses of highly intense light energy.

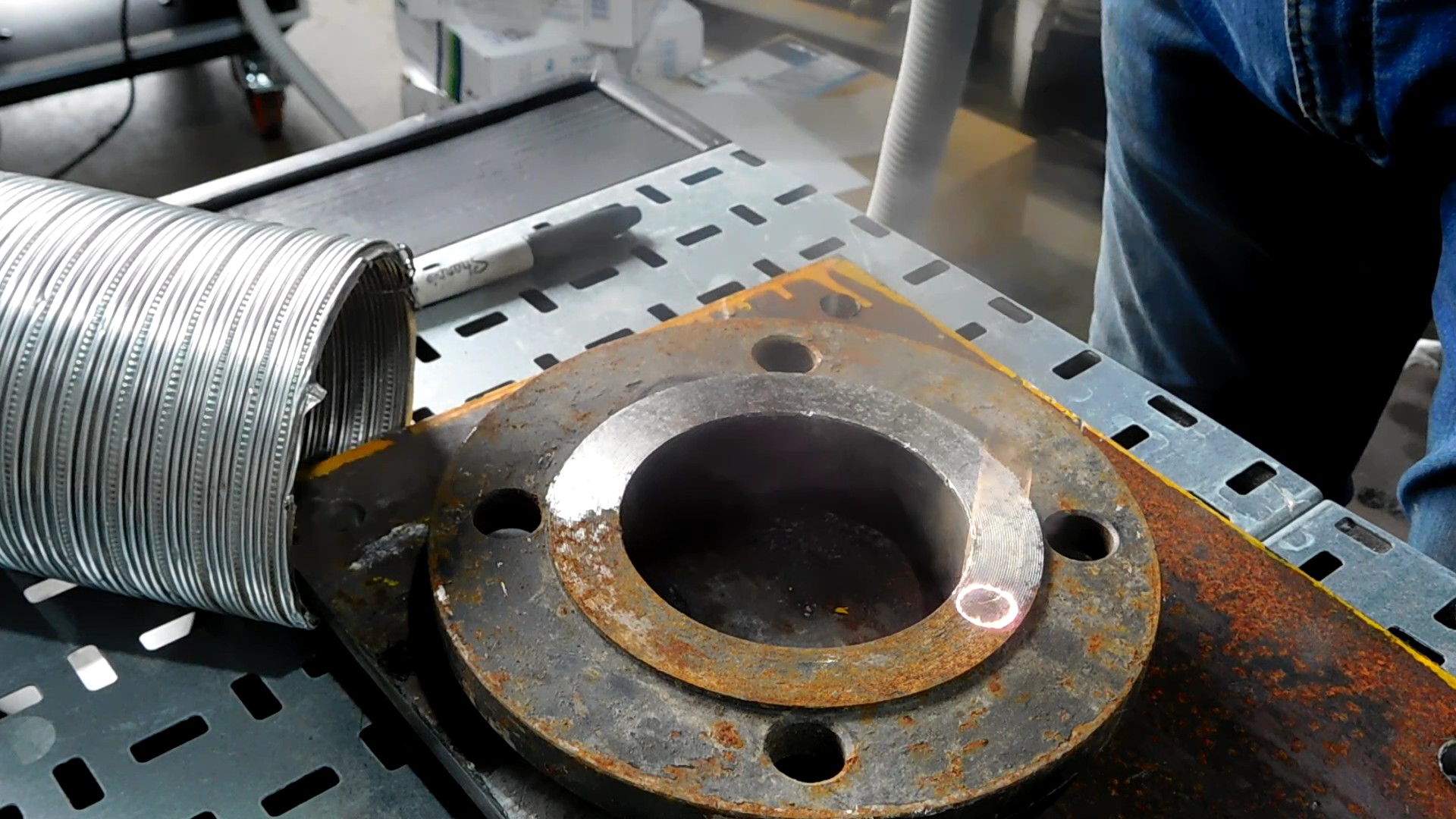

Absorption: The laser is calibrated to remove the detected contaminants (mold, grease, organic matter, rust, etc.) while leaving the substrate unblemished. The light from the laser is absorbed by the contaminants and “rejected” by the substrate.

Thermal Escalation: The absorbed laser energy induces rapid thermal escalation within the contaminants. In other words, the laser pulse vaporizes (sublimation) the contaminants, leaving the substrate untouched and unstressed.

Pressure Wave Formation: The vaporization or sublimation of the contaminants generates a shockwave that exerts significant force upon the contaminant particles. This dislodges those particles away from the surface of the substrate, allowing our extraction unit to pull them from the air (or water).

Immaculate Surfaces: Once passed under the laser, your substrate should be as clean as possible. Depending on the depth of the contaminant, it may take several passes to get to the original substrate.